Navigate

Article List

- SBMA at the Bund Summit 2021

By SBMA

- Platinum’s crucial role in global decarbonisation is driving near-term platinum investment demand

By Trevor Raymond, Director of Research, World Platinum Investment Council

- Alex Stewart International Commissions New Precious Metals Laboratory in Liverpool, UK

By Rob Smith, Business Development Executive, Alex Stewart International

- Highlights from the World Gold Council’s Inaugural Investment Summit in Singapore

By World Gold Council

- Hybrid India Gold Conference 2021

By Bullion World

- Gold Still Has Game – Even as Fed Talks Hawkishly

By Bart Melek, Global Head of Commodity Strategy, TD Securities

- Annual General Meeting 2021

By SBMA

- SBMA News

By Albert Cheng, CEO, SBMA

Article List

- SBMA at the Bund Summit 2021

By SBMA

- Platinum’s crucial role in global decarbonisation is driving near-term platinum investment demand

By Trevor Raymond, Director of Research, World Platinum Investment Council

- Alex Stewart International Commissions New Precious Metals Laboratory in Liverpool, UK

By Rob Smith, Business Development Executive, Alex Stewart International

- Highlights from the World Gold Council’s Inaugural Investment Summit in Singapore

By World Gold Council

- Hybrid India Gold Conference 2021

By Bullion World

- Gold Still Has Game – Even as Fed Talks Hawkishly

By Bart Melek, Global Head of Commodity Strategy, TD Securities

- Annual General Meeting 2021

By SBMA

- SBMA News

By Albert Cheng, CEO, SBMA

Alex Stewart International Commissions New Precious Metals Laboratory in Liverpool, UK

By Rob Smith, Business Development Executive, Alex Stewart International

Published on December 10, 2021

ROB SMITH works as Business Development Executive within Alex Stewart International’s Metals and Minerals Commercial Team. The team are responsible for global sales and business development for the Alex Stewart International (ASi) Group, which is one of the world’s leading providers of inspection, sampling and analysis services to the commodities industry. In particular, Rob focuses on the group’s inspection and analysis business for Precious Metals materials and related products. Prior to joining ASi, Rob worked for over 10 years as a Commodities Research Analyst covering the base and precious metals markets.

In case of any enquiries, Rob can be contacted on rob.smith@alexstewartinternational.com

* This article was published in partnership with Alex Stewart International

Although fire assay is an ancient technique, it is still considered the standard method for determining the gold content in a range of precious metal bearing materials.

This method has, however, also been supplemented by the use of modern-day instrumentation and the continuous advancement in technologies, which have improved the efficiency and accuracy of the precious metals assaying process. Reflecting these ongoing developments, ASi has continued to invest in its precious metal testing facilities and in early 2021 the company commissioned a new modernised Fire Assay Laboratory at its Head Office Laboratories in the United Kingdom (UK).

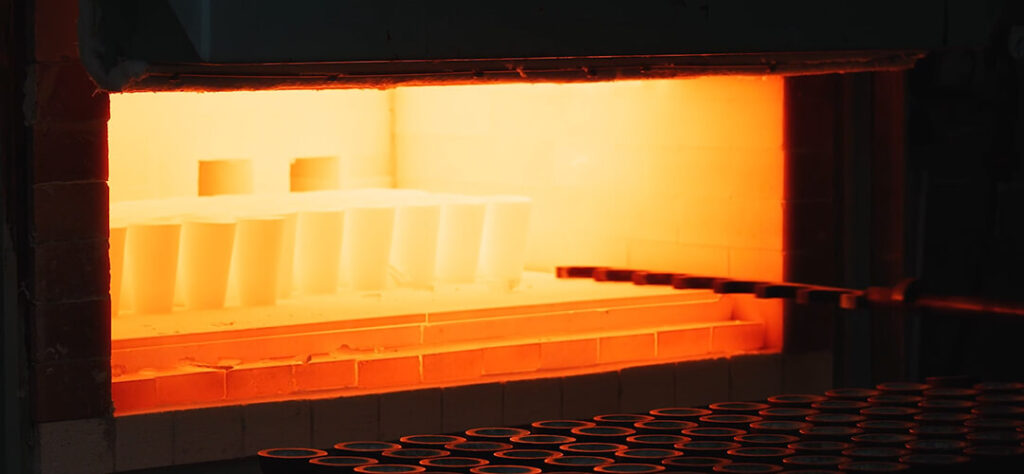

Investments include the installation of state-of-the-art multi-pour fire assay furnaces, which have resulted in significantly increased assaying capacity. These furnaces are used in the initial fusion stage of the gold assaying process and are an integral part of the company’s fire assay laboratory. Within this process, the precious metal bearing sample is mixed with a fluxing agent with lead added as a collector. The samples are then heated at high temperatures, resulting in the fusion of the precious metals and the lead, which separate from the silicate slag and form a button in the bottom of the crucible. The samples are removed from the furnace, cooled and the button is then separated from the slag.

The precious metals are then extracted by a process known as cupellation, whereby the button is placed in a cupel and heated in a cupellation furnace. During this process, the lead oxidises and is absorbed into the cupel, leaving a precious metal bead. The gold content of the bead is determined either gravimetrically or is dissolved in aqua regia to be analysed by one of several instrumental methods. Silver content can also be determined.

One such instrumental method is Inductively Coupled Plasma-Optical Emission Spectrometry (ICP-OES) which is utilised extensively for the determination of precious metals content within a range of low and high grade precious metal bearing materials. As part of the recent investment, ASi have also modernised the ICP-OES laboratory with hi-tech equipment. Along with the upgrade to the furnaces, these investments have increased assaying capabilities significantly and will help to ensure swift result turn-around times and the high quality accurate analysis which is expected within the industry.

To coincide with the commissioning of the new fire assay laboratory, a new video walkthrough of the fire assaying process was filmed at the Head Laboratories in Liverpool, UK, which can now be viewed online at www.alexstewartinternational.com

WIDE RANGE OF TESTING

Within ASi’s precious metals laboratories, chemists are able to produce both accurate and precise results using a blend of modern instrumental and classical techniques for all precious metal bearing materials. These include concentrates, dore, high-grade bullion, jewellery scrap, electronic scrap, PGMs, catalysts, sweeps, slimes, sludges and residues. ASi provides both party and umpire analysis services, as well as analysis services for quality control purposes, and are approved by CME Group for analysis of all COMEX and NYMEX metals products.

ASi also provides analysis services across a range of other metals, minerals and commodities at its extensive laboratories in the UK and worldwide. All assaying methods are both time-tested and in-house developed with validation by the use of certified reference materials. External validation is also employed where samples are analysed for round robin exercises and technical committees.

ACCURATE PRECIOUS METAL VALUATION

ASi also provides a key range of inspection and sampling services to its worldwide clients. The company’s team of experienced inspectors attend at ports, smelters/refineries, processors, reclaimers and storage facilities worldwide to witness all stages of the weighing/sampling processes, including weighing, melting, incineration, screening, blending, sampling, moisture determination, loss on ignition (LOI), quality sample preparation and sample sealing.

Whether it be concentrates, dore, electronic scrap, jewellery scrap, PGM catalysts or refinery sweeps and residues, all of ASi’s experienced representatives are fully conversant with the various materials, processing facilities and sampling procedures employed at the major receivers worldwide. By having another pair of eyes and ears in attendance, inspectors help to eliminate possible human error and provide verification for all weights, data and calculations.

All operations are followed in accordance with agreed procedures so that material is satisfactorily recovered from all processes and equipment. Finally, of upmost importance, ASi ensures that representative samples have been drawn and that they are prepared and sealed in the presence of an inspector. By ensuring that the clients’ material is correctly handled, sampled and subsequently analysed, it is able to help all valued customers to reach a commercial settlement which is reflective of the true value of their shipment.

REFINERY ASSESSMENTS AND INVENTORY AUDITS

Reflecting its expertise and experience within the precious metals industry, ASi is also an approved supervisor for the proactive monitoring of refineries (PAM) on the LBMA Good Delivery Gold and Silver lists and is also a supervisor to the LPPM Good Delivery system for Platinum and Palladium. The company’s inspectors also attend at refineries to witness sampling and monitoring as part of the purity testing requirements for CME (COMEX/NYMEX) brand applications. In addition, ASi is accredited to perform inspections in accordance with DMCC Dubai Good Delivery (DGD) and Market Deliverable Brands (MDB) testing requirements.

Furthermore, another growing area of business involves the provision of independent bar auditing and inventory services to the investment community. These audits involve visiting secure storage locations to count bar quantities and to verify all bar details, markings and quality against official inventory lists supplied by the custodian vault and the client. ASi attends at approved bullion vaults worldwide on a regular basis, including in the UK, Switzerland, Germany, the Netherlands, China, Hong Kong, Singapore, India, Canada and the United States.

From mine to market, ASi’s strategically placed network has its customers’ inspection and analysis needs covered and looks forward to continuing to serve the global Precious Metals market.

ABOUT ALEX STEWART INTERNATIONAL

Alex Stewart International (ASi) is dedicated to helping clients obtain the correct valuation for their Precious Metal Materials. This is achieved through the provision of internationally accredited inspection, sampling and analytical services. Representing the ongoing growth in ASi’s Precious Metals Business and its continued drive to provide clients with the best possible service, the company is pleased to announce that it has recently commissioned an upgraded Precious Metals Fire Assay Laboratory at its Head Office Laboratories in Liverpool, United Kingdom.

ROB SMITH works as Business Development Executive within Alex Stewart International’s Metals and Minerals Commercial Team. The team are responsible for global sales and business development for the Alex Stewart International (ASi) Group, which is one of the world’s leading providers of inspection, sampling and analysis services to the commodities industry. In particular, Rob focuses on the group’s inspection and analysis business for Precious Metals materials and related products. Prior to joining ASi, Rob worked for over 10 years as a Commodities Research Analyst covering the base and precious metals markets.

In case of any enquiries, Rob can be contacted on rob.smith@alexstewartinternational.com

* This article was published in partnership with Alex Stewart International